Stainless steel with different vegetable oil based cutting fluid at extreme pressure condition.

Vegetable based cutting fluid an environmental alternative to grinding process.

The machining is carried out in a turning centre.

Their constituents have been cultivated and refined for specific performance properties and technical requirements.

Thus this work presents a new water based grinding fluid formulation able to meet both the performance and environmental requirements for cbn grinding.

Therefore a need arose to identify eco friendly and hazard free alternatives to conventional mineral oil based metal working fluids.

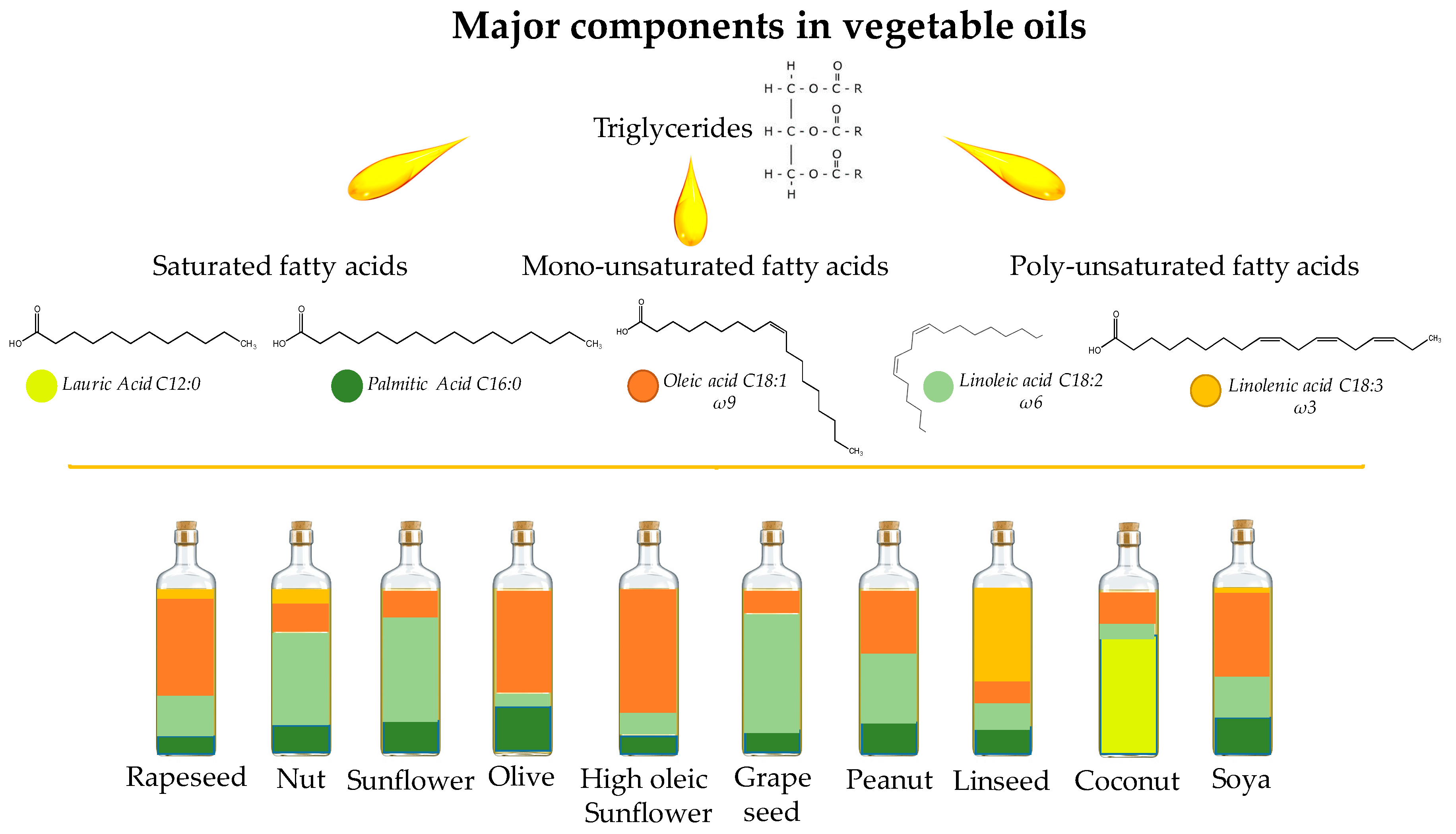

Vegetable oil based coolants are plant based products.

Vegetable oils have become identified world over as a potential.

1 to develop a new ecofriendly cutting fluid based on vegetable oil to replace the existing conventional oil.

Alves sm oliveira jfg 2008 vegetable based cutting fluid an environmental alternative to grinding process.

Thus this work presents a new water based grinding fluid formulation able to meet both the performance and environmental requirements for cbn grinding.

Vegetable based cutting fluids vbcfs were an oil in water emulsion type which consisted of base oil surfactant s and additives in the formula to meet the specifications such as resistance to bacterial growth corrosion foaming and wear dickinson 1992.

The growing demand for biodegradable materials has opened an avenue for using vegetable oils as an alternative to petroleum based polymeric materials.

The new fluid concept consisting of a high concentration up to 40 of sulfonate vegetable oil in water is proposed and tested.

Request pdf vegetable based cutting fluid an environmental alternative to grinding process the development of lubricants like cutting fluids was traditionally based on mineral oil as a base.

The main objectives of this work are the following.

Among them palm oil obtained the lowest milling force fx 309 n fy 154 n at 7 76 and 13 6 lower than that of synthetic cutting fluids.

Thus neem oil and water melon seed oil was studied and made as an alternative as cutting fluids in order to improve the life of the tool improve surface finish in work piece prevent corrosion in a steel maintaining dimensional accuracy.

The lubricating film layer provided by vegetable oils is intrinsically strong and lubricious.

Rather than coating the tool to machine high strength alloys it found to be a simple alternative.